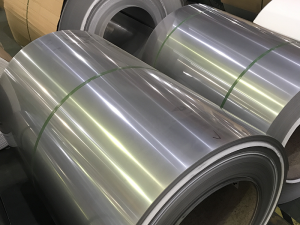

410S Stainless hlau kauj

Kev piav qhia

Specifications:

1. Txuj: ASTM A240, JIS G4304, EN10088

2. Qib: 200series & 300series & 400series

3. Thickness: 0.03mm - 6.0mm

4. Dav: 8mm-600mm

5. Ntev: raws li cov neeg siv khoom thov

6. Nto: 2D, 2B, BA, Daim iav tiav, N04, Plaub Kab, Matt tiav, 6K, 8K

7.Technology: txias drawn / txias dov / kub dov

Khoom siv:

| Hom | Qib | Qib | Chemical Cheebtsam% | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Lwm yam | |||

| Austenitic | 201 | SUS 201 | ≤ 0.15 | 16.00-18.00 Nws | 3.50-5.50 Nws | 5.50—7.50 Nws | ≤ 0.060 | ≤ 0.030 | - | ≤ 1.00 | - | ≤ 0.25 | - |

| 202 | SUS 202 | ≤ 0.15 | 17.00-19.00 Nws | 4.00-6.00 Nws | 7.50-10.00 Nws | ≤ 0.060 | ≤ 0.030 | ≤ 1.00 | - | ≤ 0.25 | - | ||

| 301 | 1.4310 Nws | ≤ 0.15 | 16.00-18.00 Nws | 6.00-8.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | ≤ 0.10 | - | |

| 304 | 1.4301 ib | ≤ 0.07 | 17.00-19.00 Nws | 8.00-10.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 304l ua | 1.4307 ib | ≤ 0.030 | 18.00-20.00 Nws | 8.00-10.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 3 04h | 1.4948 ib | 0.04-0.10 Nws | 18.00-20.00 Nws | 8.00-10.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 309 | 1.4828 ib | ≤ 0.20 | 22.00-24.00 Nws | 12.00-15.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 309s ua | * | ≤ 0.08 | 22.00-24.00 Nws | 12.00-15.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 310 | 1.4842 ib | ≤ 0.25 | 24.00-26.00 Nws | 19.00-22.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤1.50 | - | - | - | |

| 310S ib | * | ≤ 0.08 | 24.00-26.00 Nws | 19.00-22.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤1.50 | - | - | - | |

| 314 | 1.4841 ib | ≤ 0.25 | 23.00-26.00 Nws | 19.00-22.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | 1.50-3.00 Nws | - | - | - | |

| 316 | 1.4401 Nws | ≤ 0.08 | 16.00-18.50 dr hab | 10.00-14.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 2.00-3.00 Nws | ≤ 1.00 | - | - | - | |

| 316l ua | 1.4404 ib | ≤ 0.030 | 16.00-18.00 Nws | 10.00-14.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 2.00-3.00 Nws | ≤ 1.00 | - | - | - | |

| 316 Ti | 1.4571 ib | ≤ 0.08 | 16.00-18.00 Nws | 10.00-14.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 2.00-3.00 Nws | ≤ 1.00 | - | 0.1 | Ti5 (C+N) ~ 0.70 | |

| 317 | * | ≤ 0.08 | 18.00-20.00 Nws | 11.00-15.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 3.00-4.00 Nws | ≤ 1.00 | - | 0.1 | - | |

| 317l ua | 1.4438 ib | ≤ 0.03 | 18.00-20.00 Nws | 11.00-15.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | 3.00-4.00 Nws | ≤ 1.00 | - | 0.1 | - | |

| 321 | 1.4541 ib | ≤ 0.08 | 17.00-19.00 Nws | 9.00-12.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | Ti5 (C+N) ~ 0.70 | |

| 321 h ua | * | 0.04-0.10 Nws | 17.00-19.00 Nws | 9.00-12.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | Ti5 (C+N) ~ 0.70 | |

| 347 ib | 1.4550 Nws | ≤ 0.08 | 17.00-19.00 Nws | 9.00-12.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | Nb≥10 * C% -1.10 | |

| 347 h ua | 1.494 ib | 0.04-0.10 Nws | 17.00-19.00 Nws | 9.00-12.00 Nws | ≤ 2.00 | ≤ 0.045 | ≤ 0.030 | - | ≤ 1.00 | - | - | Nb≥10 * C% -1.10 | |

| Duplex | 2205 | S32205 | ≤ 0.03 | 22.0-23.0 Nws | 4.5-6.5 | ≤ 2.00 | ≤ 0.030 | ≤ 0.020 | 3.0-3.5 | ≤ 1.00 | - | 0.14-0.20 Nws | |

| 2507 ib | S32750 | ≤ 0.03 | 24.0-26.0 Nws | 6.0-8.0 Nws | ≤ 1.20 | ≤ 0.035 | ≤ 0.020 | 3.0-5.0 Nws | ≤ 0.80 | 0.5 | 0.24-0.32 Nws | ||

| Ferrite | 409 ib | S40900 | ≤ 0.03 | 10.50-11.70 dr hab | 0.5 | ≤ 1.00 | ≤ 0.040 | ≤ 0.020 | - | ≤ 1.00 | - | ≤ 0.030 | Ti6(C+N) ~ 0.50 Nb: 0.17 |

| 430 | 1 cr17 | ≤ 0.12 | 16.00-18.00 Nws | - | ≤1.0 | ≤ 0.040 | ≤ 0.030 | - | ≤1.0 | - | - | - | |

| 444 ib | S44400 | ≤ 0.025 | 17.50-19.50 Nws | 1 | ≤ 1.00 | ≤ 0.040 | ≤ 0.030 | 1.75-2.5 Nws | ≤ 1.00 | - | 0.035 ib | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensite | 410 | 1 Cr13 | 0.08-0.15 dr hab | 11.50-13.50 dr hab | 0.75 ib | ≤ 1.00 | ≤ 0.040 | ≤ 0.030 | - | ≤ 1.00 | - | - | - |

| 410 S | * | ≤ 0.080 | 11.50-13.50 dr hab | 0.6 | ≤ 1.00 | ≤ 0.040 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 420 | 2 cr13 | ≥0.15 | 12.00-14.00 Nws | - | ≤ 1.00 | ≤ 0.040 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| 420j 2 | 3 cr13 | 0.26-0.35 dr hab | 12.00-14.00 Nws | - | ≤ 1.00 | ≤ 0.040 | ≤ 0.030 | - | ≤ 1.00 | - | - | - | |

| PH | 630 | 17-4 PAB | ≤ 0.07 | 15.00-17.50 dr hab | 3.00-5.00 Nws | ≤ 1.00 | ≤ 0.035 | ≤ 0.030 | - | ≤ 1.00 | 3.00-5.00 Nws | - | 0.15-0.45 Nws |

| 631 ib | 17-7 PHN | ≤ 0.09 | 16.00-18.00 Nws | 6.50-7.50 Nws | ≤ 1.00 | ≤ 0.035 | ≤ 0.030 | - | ≤ 1.00 | ≤0.50 | - | 0.75-1.50 Nws | |

| 632 ib | 15-5 PHN | ≤ 0.09 | 14.00-16.00 Nws | 3.50-5.50 Nws | ≤ 1.00 | ≤ 0.040 | ≤ 0.030 | 2.00-3.00 Nws | ≤ 1.00 | 2.5-4.5 | - | 0.75-1.50 Nws | |

Cov ntaub ntawv yooj yim

410s Stainless Hlau Chev, nrog zoo corrosion kuj thiab machinability, nws yog lub hom phiaj dav hlau thiab cov cuab yeej txiav hlau.410S yog ib hom hlau uas tuaj yeem txhim kho corrosion kuj thiab formability ntawm 410 steel.410S yog lub zog siab steel uas tuaj yeem txhim kho corrosion kuj ntawm 410 steel.Nws yog siv rau turbine hniav thiab kub qhov chaw.

• Specifications: AISI 410s, ASTM 410s

• Kev Ua tiav: Ba nto, 2b nto, No.1 (dawb tawv nqaij), 2D nto, No.4 (frosted), HL (xov hlau kos duab), 8K nto muaj qhov zoo heev

•Mill tolerances ntawm thickness & flatness siv. Hu rau JM Steel yog tias koj xav tau qhov ntau thiab tsawg lossis cov lus qhia.

410S Cov yam ntxwv machining tshuab

1D - Qhov saum npoo muaj cov duab tsis tu ncua, tseem hu ua pos huab.

Kev siv thev naus laus zis: kub dov + annealing txhaj tshuaj peening pickling + txias dov + annealing pickling.

2D - Ib me ntsis silvery dawb xim.

Kev siv thev naus laus zis: kub dov + annealing txhaj tshuaj peening pickling + txias dov + annealing pickling.

2B - Nyiaj dawb nrog zoo gloss thiab flatness dua 2D nto.

Kev siv thev naus laus zis: kub dov + annealing txhaj tshuaj peening pickling + txias dov + annealing pickling + quenching thiab tempering dov.

Ba - Zoo heev nto gloss, siab reflectivity, zoo li daim iav nto.

Kev siv thev naus laus zis: kub dov + annealing tua peening pickling + txias dov + annealing pickling + nto polishing + quenching thiab tempering dov.

No.3 -- Zoo gloss, coarse grain nto.

Kev siv tshuab: polishing thiab tempering dov rau 2D lossis 2B nrog 100 ~ 120 abrasive cov ntaub ntawv (JIS R6002).

No.4 -- Zoo gloss, zoo kab ntawm qhov chaw.

Cov txheej txheem ua: polishing thiab tempering dov rau 2D lossis 2B nrog 150 ~ 180 abrasive cov ntaub ntawv (JIS R6002).

HL - Nyiaj grey nrog cov plaub hau streaks.

Kev siv thev naus laus zis: 2D cov khoom lossis 2B cov khoom lag luam nrog cov khoom tsim nyog ntawm cov ntaub ntawv abrasive rau polishing saum npoo yog cov nplej tsis tu ncua.

MIRRO -- Specular.

Kev siv thev naus laus zis: 2D cov khoom lossis 2B cov khoom lag luam nrog cov khoom tsim nyog ntawm cov khoom sib tsoo sib tsoo thiab polishing rau daim iav nyhuv.